Soluble Salts

Soluble Salts

Slide /

Overview

The presence of water soluble salts on a steel surface can significantly affect the performance of paint coatings depending on the type of paint system, the service environment, the thickness of the paint and the type and amount of the salts.

An aqueous environment is generally more aggresive where soluble salts are concerned than an atmospheric environment with pure water having a greater effect than salt water.

Types of Salt

Chlorides from the dissociaton of salts such as sodium chloride are prevalent in marine environments from seawater and salt spray and in inland locations from de-icing salts and chemical processes.

Nitrates from the dissociation of salts such as ammonium nitrate and sodium nitrate are found in fertilizers and oxides of nitrogen can chemically react to produce nitrates

Sulphates are found from the combustion of coal and oil and can form sulphuric acid.

Service Environment

Generally soluble salts have a more deleterious effect on paint coating performance in an immersion situation where blistering is the most common type of failure.

In an atmospheric environment under-film corrosion is more common where the conditions are high humidity and intermittent wetting.

Where long periods of exposure to condensation occur blistering of the coating is often the predominating type of failure as time of wetness and the type of water become important factors.

Paint Systems

Paint systems vary in their tolerance to soluble salts.

Zinc silicate coatings can react with salts hence reducing their effect.

Coatings containing laminar pigments and those which are densely cross-linked are less permeable to moisture and hence more resistant to blistering.

Generally the greater the coating thickness the greater is the resistance to blistering and most coatings will have a tolerable salt level, depending on the environment, below which there is a low risk of failure by blistering.

The overall resistance of the coating to soluble salts will be influenced by both generic type and formulation.

Permeability

As organic coatings are semi-permeable membranes, liquids can diffuse through them.

The coatings will attain equilibrium with their environment by absorbing or releasing water depending on the prevailing relative humidity and the rate and degree to which this occurs will be influenced by factors such as the generic type of coating and the pigmentation where laminar pigments such as MIO provide more of a barrier than normal pigments.

Although it has been shown that salts such as sodium chloride can transport through paint coatings as their ions (Na+ and Cl-) this ionic permeability is very much lower than that of water and many films can be considered impermeable to dissolved solids.

Osmotic Blistering

Where water soluble salts are present at the coating/substrate interface or between coats in a multicoat system and the coating is in contact with an aqueous environment blistering can occur as water absorbed by the coating is transported to the location of the salts.

A concentration gradient will exist between the aqueous solution at the site of the salts and the external aqueous environment in contact with the coating surface.

Osmotic Blistering

Existing coatings must be clear of soluble salts before being overcoated with fresh coatings, especially in aqueous environments.

Blistering will occur around the salt contaminants as illustrated.

The pressure pushes the coating out into a dome shape and the size will depend on the amount of contaminants, coating type and thickness and environments.

Osmotic Blistering

Because of this concentration gradient water will be drawn through the film from the more dilute external solution to the site of the soluble salts until the salt concentrations are equal.

If for example pure water is the external aqueous environment more water will be transported through the film than if the external environment was salt water.

Osmotic Blistering

As the process continues a pressure builds up at the site of the salt due to the increase in volume and when it becomes high enough to overcome the adhesion of the coating a blister will develop.

Blister formation slows down with time as the salt concentration decreases and the osmotic pressure becomes less.

The pressure that develops inside the blister due to the increased water ingress can cause the blister to break.

Corrosion Within the Blister

Corrosion under a blister cap formed on a steel substrate will occur and its rate will primarily depend on the degree of oxygen permeation through the coating.

Ferrous ions initially formed will consume oxygen producing soluble ferrous corrosion products which will be oxidised to the ferric state and form a deposit , normally black in colour, on the underside of the blister cap.

The access of oxygen to the internal of the blister will be hindered by these deposits but access would be available at the periphery of the blister and the cathodic sites will move outwards.

Corrosion Within the Blister

The area of the blister can expand as corrosion products are produced and underfilm corrosion occurs.

This is often characterised by black circular areas of corrosion on the steel in way of the blister dome.

If the adhesion of the coating to the steel at the periphery of the blister is such, as to resist the spread of underfilm corrosion, the pressure created by a build up of corrosion product under the blister cap can cause the blister to break allowing ingress of other species and further corrosion.

Sampling

Before analysis for soluble salts can be undertaken they have to be extracted from the surface in an aqueous solution.

The method described in ISO 8502-6, “The Bresle method” utilises an adhesive patch designed to hold the extraction liquid in a central compartment.

The self adhesive patch is attached to the surface and the extraction liquid injected into the compartment with a syringe.

The liquid is sucked back into the syringe and re-injected with the process being repeated a number of times before the liquid, now containing the soluble salts is transferred to a container for analysis.

Qualitative Tests

These test indicate whether a contaminant is present but not the exact amount.

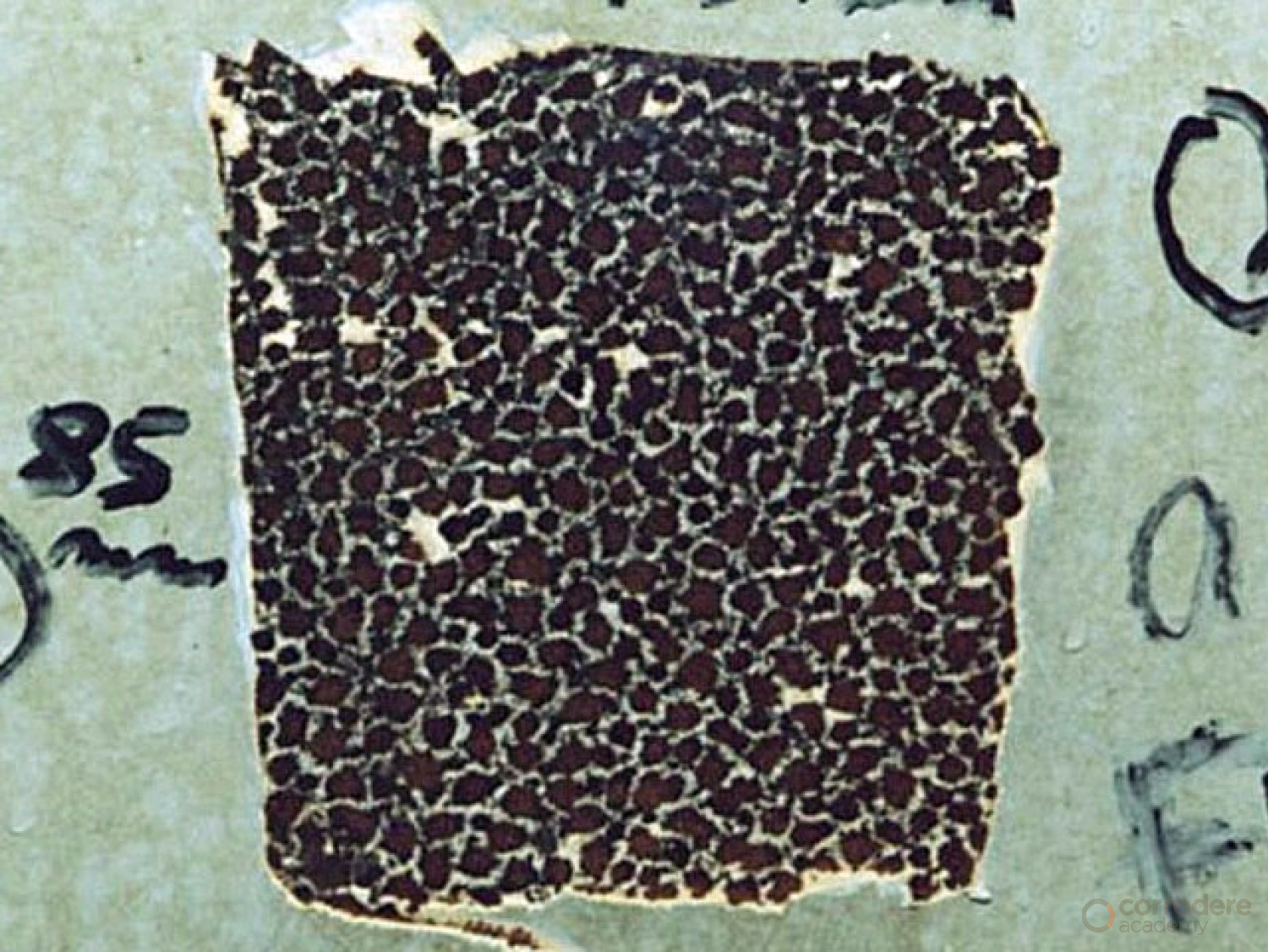

Potassium ferricyanide is used to detect the presence of ferrous ions.

In the test a fine mist of water is sprayed onto a small area of the blast cleaned surface and allowed to evaporate.

The test paper previously soaked in the potassium ferricyanide solution and allowed to dry is pressed onto the surface for 2 to 5 seconds.

Any soluble salts present will react with the ferricyanide to produce a prussian blue complex appearing as blue dots on the test paper.

Qualitative Tests

If a few drops of silver nitrate solution are placed on an area of the blast cleaned surface chlorides will show as white spots which are precipitated silver chloride. It should be noted that this test is not as sensitive as other methods.

Merckoquant test strips are available to determine semi-quantitatively many ions including chloride, iron, nitrate and sulphate.

The strip is dipped into the extracted liquid, the excess water shaken off and the colour produced compared with the scale provided.

Different test strips are used for different ions and the deeper the colour the higher the concentration.

Quantitative Tests

ISO 8502-2 Laboratory determination of chloride on cleaned surface.

The extraction liquid from the Bresle patch can be used or a known area swabbed with an absorbent cotton pad soaked in water and the washings squeezed into beaker and filtered prior to making up to 50ml in a volumetric flask.

20ml of the liquid is placed in a conical flask, 5 drops of diphenylcarbazone/bromophenol blue indicator added, acidified with nitric acid if necessary until the colour is yellow, and titrated with a standard volumetric solution of mercury (11) nitrate solution until the colour changes to a blue-violet.

From the volume of titrant required the amount of chloride per unit area can be calculated.

Quantitative Tests

ISO 8502-5 Measurement of chloride by the ion detection tube method.

The extraction liquid from the Bresle patch can be used or a known area swabbed with an absorbent cotton pad soaked in water as described in the standard.

The method employs glass detection tubes containing silver chromate in a silica carrier which undergoes a change in colour on reaction with chloride ions.

Both ends of the tube are cut off and one end immersed vertically in the extraction liquid. The liquid rises up the tube and the chloride concentration can be read off the scale engraved on the tube at the highest point where a slight colour change has occurred.

The amount of chloride per unit area can be calculated from the tube reading, the sampled area and the extract volume.

Quantitative Tests

ISO 8502-9 Field method for the conductometric determination of water soluble salts.

The salts are removed from the surface by the Bresle patch method using water as the solvent.

The electrodes of a conductivity meter are immersed in the liquid and the conductivity expressed as micro Siemens per centimetre (µS/cm) recorded.

A simplified formula is provided in the standard to calculate the surface density of the salts.

N.B. The method measures total ionic contaminants and does not determine the individual surface densities of for example chlorides and sulphates.

Quantitative Tests

ISO 8502-10 Field method for the titrimetric determination of water soluble chloride.

The extraction liquid from the Bresle patch can be used or any other convenient method.

The reactants are in four solutions:

Solution A - diphenylcarbazone/bromophenol blue indicator

Solution B – 0.5 mol/L Nitric acid

Solutions C and D – Mercuric nitrate titrant (the C and D solutions are of different concentration to cater for high and low chloride concentrations)

The extract solution is placed in a beaker and 2 drops of solution A are added followed by drops of solution B until it turns yellow.

Drops of solution C or D are added slowly until the solution colour changes to blue.

From the number of drops used the surface density of chloride can be calculated.

Quantitative Tests

ISO 8502-11 Field method for the turbidimetric determination of water soluble sulphate.

The extraction liquid from the Bresle patch can be used or from any other convenient method.

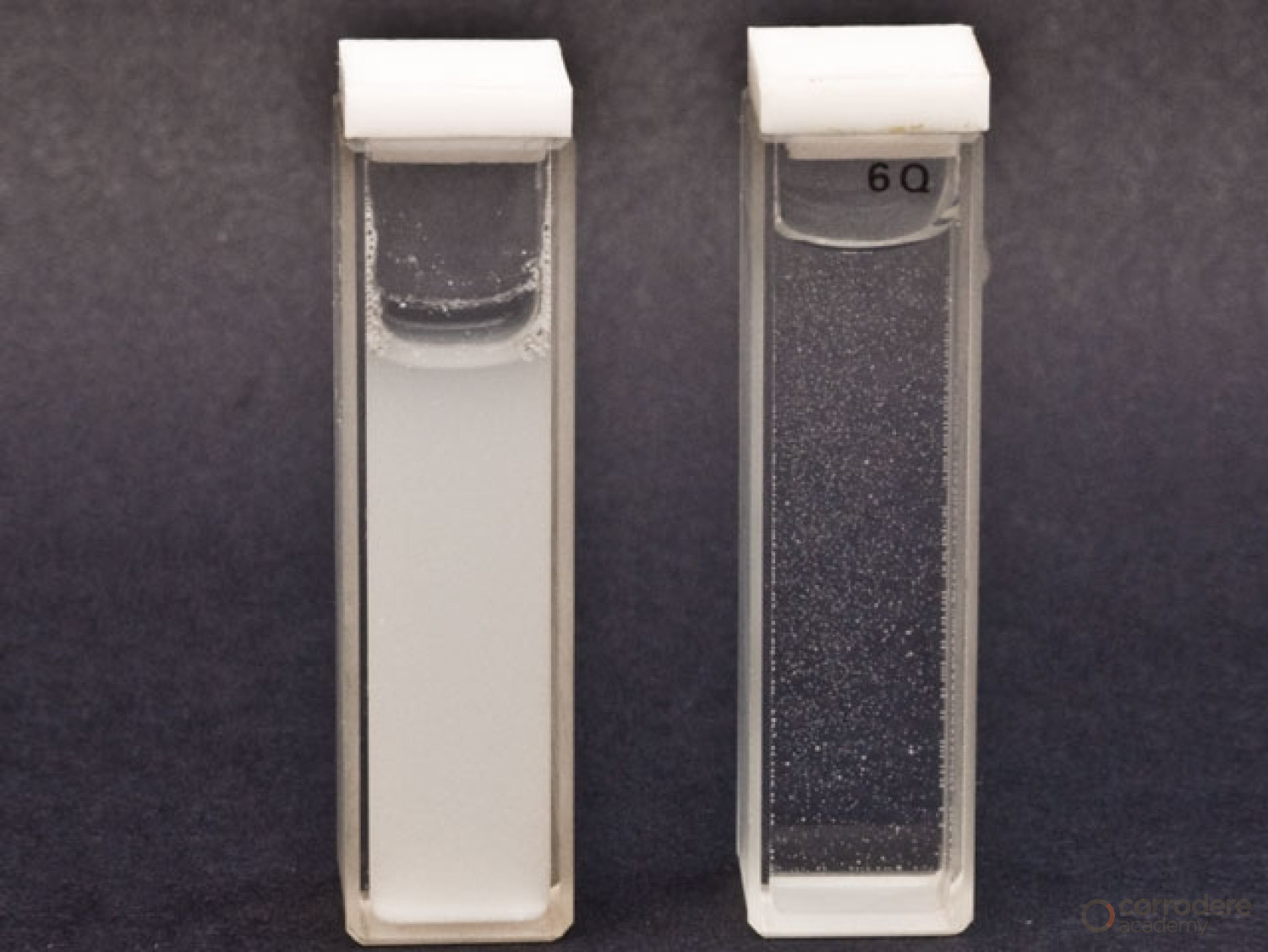

The precipitant, usually a solution of barium chloride, and a flocculant are added to the extraction liquid. If sulphate is present it is precipitated as colloidal barium sulphate.

A turbidimeter is used to measure the spectral absorbance of the dispersion which is related to the sulphate content.

From the results the surface density of the sulphate can be calculated.

Quantitative Tests

ISO 8502-12 Field method for the titrimetric determination of water soluble ferrous ions.

The extraction liquid from the Bresle patch can be used or any other convenient method.

The extracted liquid is placed in a plastic beaker, 1 ml of diphenylamine sulphonate indicator solution added, followed by 4 ml of phosphoric acid solution and titrated dropwise with a standard volumetric solution of potassium dichromate until the colour changes through a greyish blue to violet.

From the number of drops of titrant required the amount of chloride per unit area can be calculated.

Quantitative Tests

Instrumental method for total salt concentration by conductivity (Limpet cell).

A number of instruments are available and all operate on the same general principal.

The cell containing an electric stirrer is attached to the steel surface by inbuilt magnets in the base and seals against the surface with a rubber gasket.

Water is injected into the cell, the stirrer switched on for a set period of time and after switching off the conductivity can be read from the attached digital display expressed in micro Siemens per centimetre (µS/cm) .

Depending on the instrument the surface density of the salts can be automatically displayed. The results may also be able to be displayed as equivalent chloride or sodium chloride where all of the salts are assumed to be from sodium chloride.

N.B. The method measures total ionic contaminants and does not determine the individual surface densities of for example chlorides and sulphates.

SSPC Technology Guide 15

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (1)

This guide includes the parts of ISO 8502 referenced earlier and additionally describes other methods of retrieval and analysis of soluble salts both in the field and the laboratory.

The following slides provide an outline of these additional methods.

SSPC Technology Guide 15

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (2)

Retrieval methods

Three classes are listed:

Class A – Involves the extraction liquid being held in contact with the surface using a latex patch cell (A1) or sleeve (sock) (A2). The liquid can be massaged through the film to aid dissolution of the salts.

Class B – Involves a methodology for keeping a known volume of liquid within a measured area of the surface. B1 - Swabbing or washing with cotton swabs and deionized water.

B2 – Extraction of the salts by placing a pre-wetted filter paper on the surface.

Class C – Involves immersing the entire surface in boiling water and hence is only applicable for use in the laboratory. The method uses a predetermined volume of extraction liquid and a known surface area.

SSPC Technology Guide 15

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (3)

Extract solution

All retrieval methods use deionized or distilled water (reagent water) with a maximum conductivity of 5µS/cm or a proprietary solution.

Proprietary solutions may be supplied with commercial extraction kits and should only be used for the soluble salts described in the kit instructions. They are not normally suitable for measuring the conductivity of extracted solutions.

Each of the retrieval methods is described in detail in the guide and the student should read that section of the guide carefully.

SSPC Technology Guide 15:

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (4)

Analytical methods

Methods are described for the quantitative analysis of the following:-

Conductivity – This is a measure of the total dissolved salts and procedures for two types of meters are described. The “pocket” meter which operates by placing the probes into the liquid to be analysed and the “cup-type” where the liquid is place in a cup that forms part of the meter. A special meter for analysing the filter paper extract from extraction method B2 is also described.

SSPC Technology Guide 15

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (5)

Analytical methods

Soluble chloride ion – Four methods are described:-

a) An ion detection tube as described in ISO 8502-5 which can detect chloride levels in the range 1 to 2,000 ppm.

b) A paper strip method which can detect chloride levels in the range 30 to 600+ ppm.

c) A titration method based upon ISO 8502-10 (withdrawn)

d) A laboratory reference titration method based on ISO 8502-2

SSPC Technology Guide 15

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (6)

Analytical methods

Soluble ferrous ion – A quantitative and a qualitative method are described.

- Quantitative – In this method a test strip that forms a red colour in the presence of ferrous ions by reaction with 1,10 phenanthroline is moistened with the extraction liquid. The intensity of colour provides an indication of ferrous ion concentration as low as 0.5 ppm.

- Qualitative – A blotting paper treated with potassium ferricyanide solution is moistened and pressed onto the surface. Ferrous ions are indicated as blue spots on the blotting paper. Sensitivity is less than 1 ppm.

SSPC Technology Guide 15

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (7)

Analytical methods

Soluble sulphate ion – A visual and an instrumental method are described. Both methods work on the principle that the addition of a solution of barium chloride to the extraction liquid will become turbid (turn cloudy) if sulphate ions are present.

- Visual method – This involves the comparison of the cloudiness produced in the test liquid with panes of plastic with different degrees of cloudiness equivalent to different sulphate concentrations under the test conditions. The minimum level of sulphate concentration is approximately 20 ppm.

- Instrumental – The instrument measures the turbidity of the solution after barium chloride has been added over the range 1 to 200 ppm.

SSPC Technology Guide 15

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (8)

Analytical methods

Soluble nitrate ion – The method involves the use of a paper strip that changes colour when dipped into a solution containing nitrate ions. The colour depth is compared to a scale which indicates the concentration in a detection range up to 50 ppm.

Appendices describe in detail the boiling extraction method, the determination of surface concentration from solution concentration, and the determination of equivalent concentration from conductivity (chloride and total salt).

SSPC Technology Guide 15

Field Methods for the Retrieval and Analysis of Soluble Salts on Steel and Other Nonporous Surfaces (9)

Extraction Efficiency

This is defined as the quantity of soluble salt that can be retrieved from the surface as a percentage of the total amount present.

The extraction efficiency is affected by a number of factors including:-

- Method of extraction

- Proficiency of the operator

- Degree of surface roughness

- Size of the extraction area

- Type and concentration of the soluble salts

- Degree of corrosion and pitting of the substrate

- Extraction time

- Method of contamination (natural or artificial)

SaltSmart

A hand held, automated method for determination of soluble salts by conductivity measurement on flat and curved surfaces as an alternative method to the Bresle patch (ISO 8502-9)

It is comprised of a one-time-use disposable sensor, and a special meter to obtain readings.

PROCESS STEPS

1. Place the included ampoule containing pre-measured de-ionized water onto the SaltSmart ™ device.

- Use a strip of painters tape or other suitable no-residue tape to hold the sensor onto the surface under test.

- Wait approximately 8 minutes, then take the device off the surface and place into the SaltSmart ™ meter, and read the value on the backlit display

- The SaltSmart ™ meter records the date, time and surface salt concentration (up to 255 readings) for easy download through USB connection.

SSM

A hand held, automated method for determination of soluble salts by conductivity measurement on flat and curved surfaces as an alternative method to the Bresle patch (ISO 8502-9)

PROCESS STEPS

- Attach meter to surface

- Inject deionized water into SSM with one press of the dose bottle

- Press “Start”: SSM automatically agitates solution, takes measurement, displays the result on LCD screen and stores data in memory.

- Remove SSM and wipe remaining water from surface.

- Clean meter by flushing SSM with deionized water.

All data is stored electronically and can be downloaded to any PC spreadsheet programme Electronic data can be exchanged into a Coating Technical File (CTF).

Summary

Within this training unit we have discussed the different types of soluble salts and how these salts affect a coatings performance. We discussed permeability of coating systems and osmotic blistering of a coating applied over a surface with soluble salts present.

We also discussed the various methods of testing for soluble salts including the sampling and analysis which includes ISO Standards and SSPC guides.

-1.jpg?w=1500&h=1126&fit=crop&mark=logo.png&markw=200&markpos=bottom-right&markpad=20&markalpha=35&s=f90ba60c8a4da77714b5148de37f7942)

-1.jpg?w=750&h=563&fit=crop&mark=logo.png&markw=200&markpos=bottom-right&markpad=20&markalpha=35&s=e91ca4ecf0a00ab8d0e7a0d31d1d4d4c)

-1.jpg?w=1500&h=1126&fit=crop&mark=logo.png&markw=200&markpos=bottom-right&markpad=20&markalpha=35&s=01bd2fa6e058dca497a7c953e9a1d1ef)

-1.jpg?w=750&h=563&fit=crop&mark=logo.png&markw=200&markpos=bottom-right&markpad=20&markalpha=35&s=d64fc061413e82074c5d56c78207877e)

.jpg?w=1500&h=1126&fit=crop&mark=logo.png&markw=200&markpos=bottom-right&markpad=20&markalpha=35&s=6d6c8f73b15c8dd9d3e6ae3cd5b86477)

.jpg?w=750&h=563&fit=crop&mark=logo.png&markw=200&markpos=bottom-right&markpad=20&markalpha=35&s=823c2194a2acfcc8287aabf4d1d9a0c1)